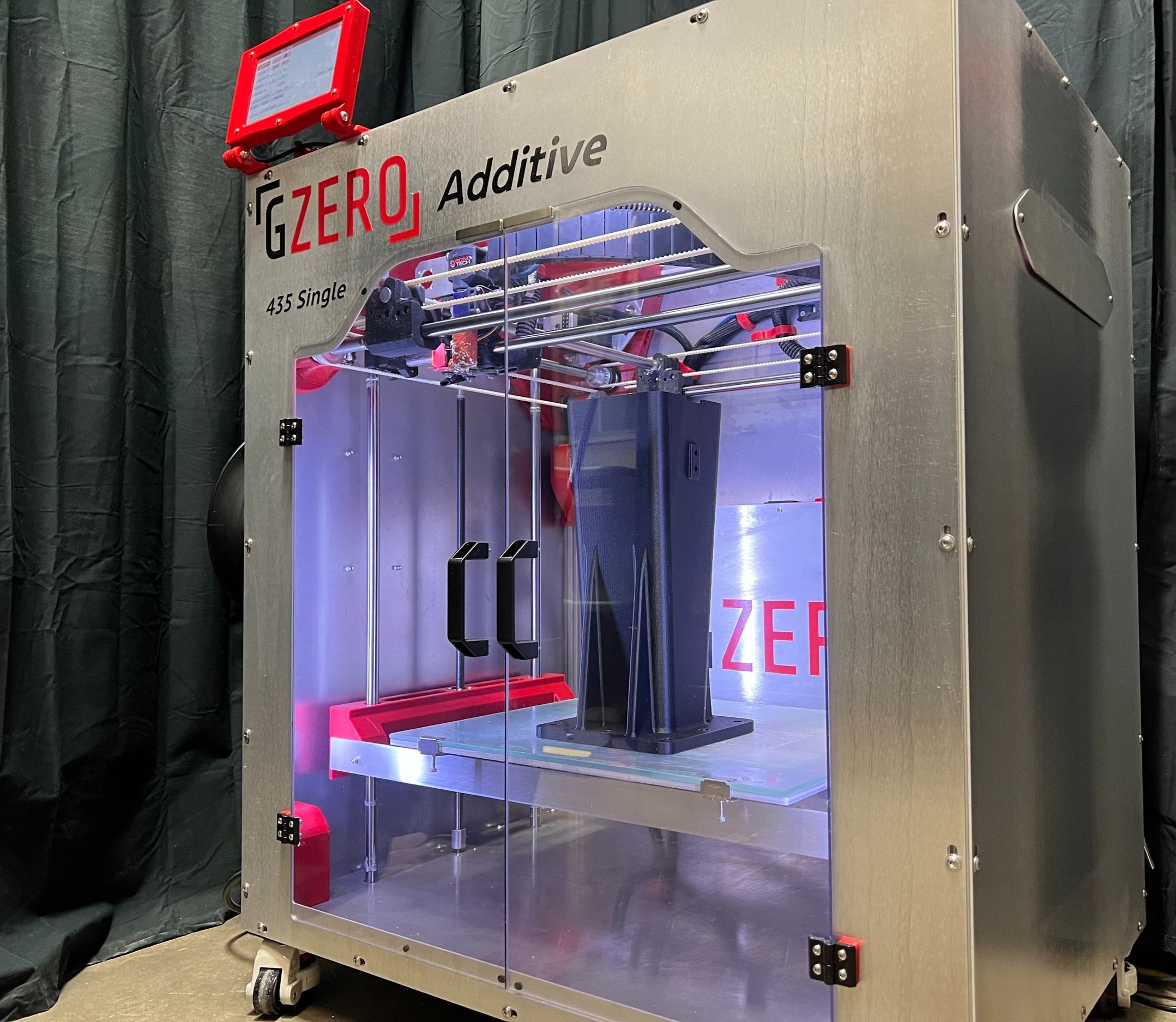

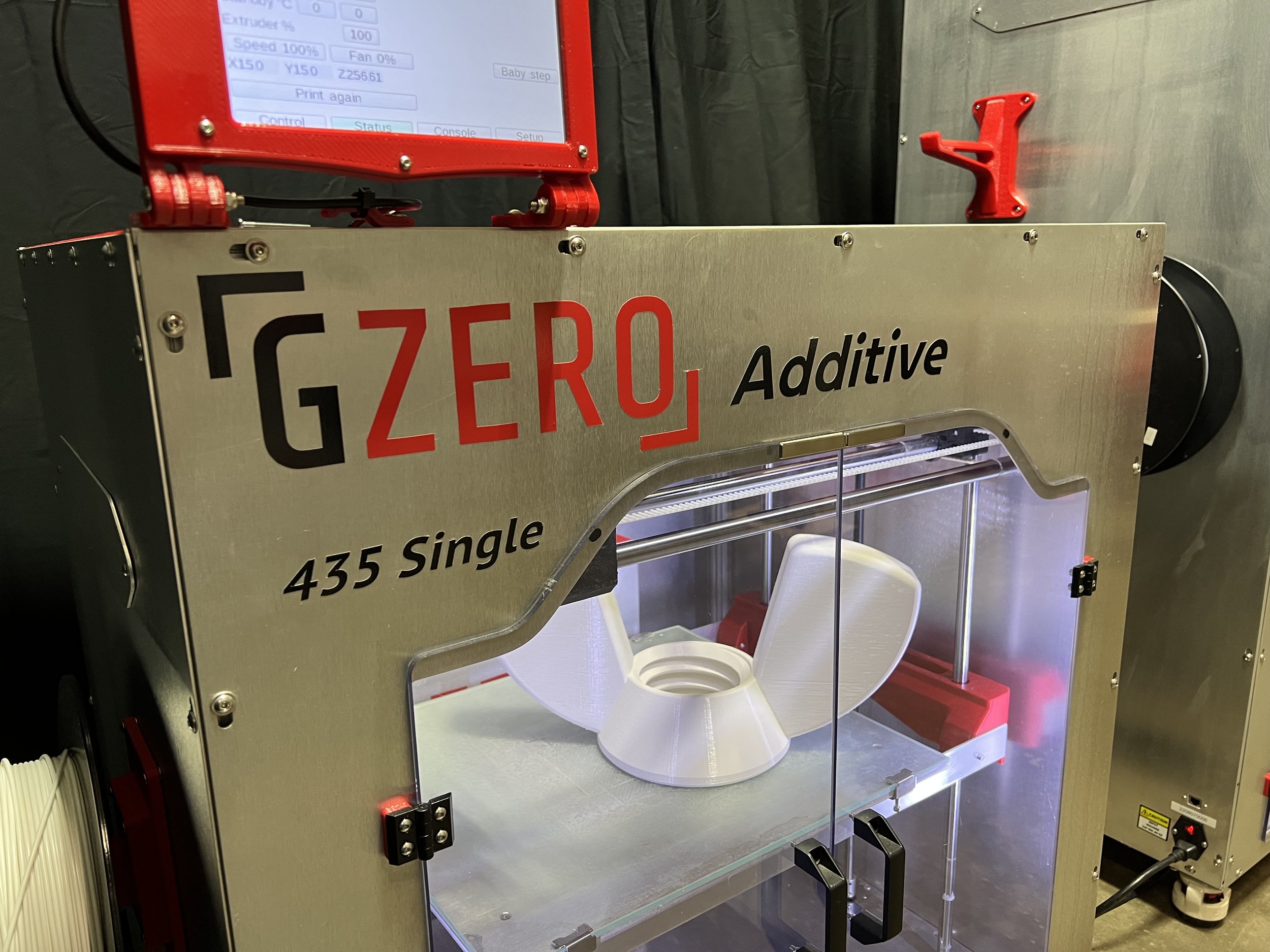

Two Models to Choose From

435

415 x 355 x 542 mm (16.3 x 13.9 x 21.3 inches)

Starting at $10,999

4310

415 x 355 x 1042 mm (16.3 x 13.9 x 41.0 inches)

Starting at $13,499

“The 435 has been a game-changer when I'm designing on a tight schedule. I can print and test functional parts in hours instead of waiting days - and spending way more - for machining.”

— Travis / Wes-Tech Automation Solutions / 435 Dual

Designed for professionals. Assembled, aligned, tuned, and ready for production.

-

Ease of Use

43 Series machines are designed with the user in mind. Automatic bed leveling, a fully enclosed build environment, and a 7” touchscreen keep productivity and success rates high. 43 Series machines are able to run on a standard 15A 120V circuit, or two machines on a 20A circuit, meaning no special wiring is required.

-

Speed

Nobody wants to wait for prints. That’s why the GZERO 43 Series features oversized motion components, able to drive the print head at 12,000mm/min and accelerate at over 1G. The standard nozzle diameter of 0.6mm allows large, structural parts to be constructed in hours instead of days.

-

Print Unrestricted

Hardened steel nozzles and dual-geared direct drive extruders are standard on GZERO Additive 43 Series machines. With no restrictions on material suppliers, users are equipped to run their favorite materials without requiring modifications. A build area of 415mm X 355mm and up to 1 meter tall allows these machines to build real parts.

“When I’m ready to add another machine to my operation, they’ll be my first and only call.”

— Andrew / FUDDCO / 4310 Dual

-

Capability

Hardened steel nozzles, all metal hot ends, and direct drive extruders mean that 43 Series machines are ready to tackle the toughest materials right from the factory. Carbon fiber filled, flexible, and metal filled filaments are no challenge.

-

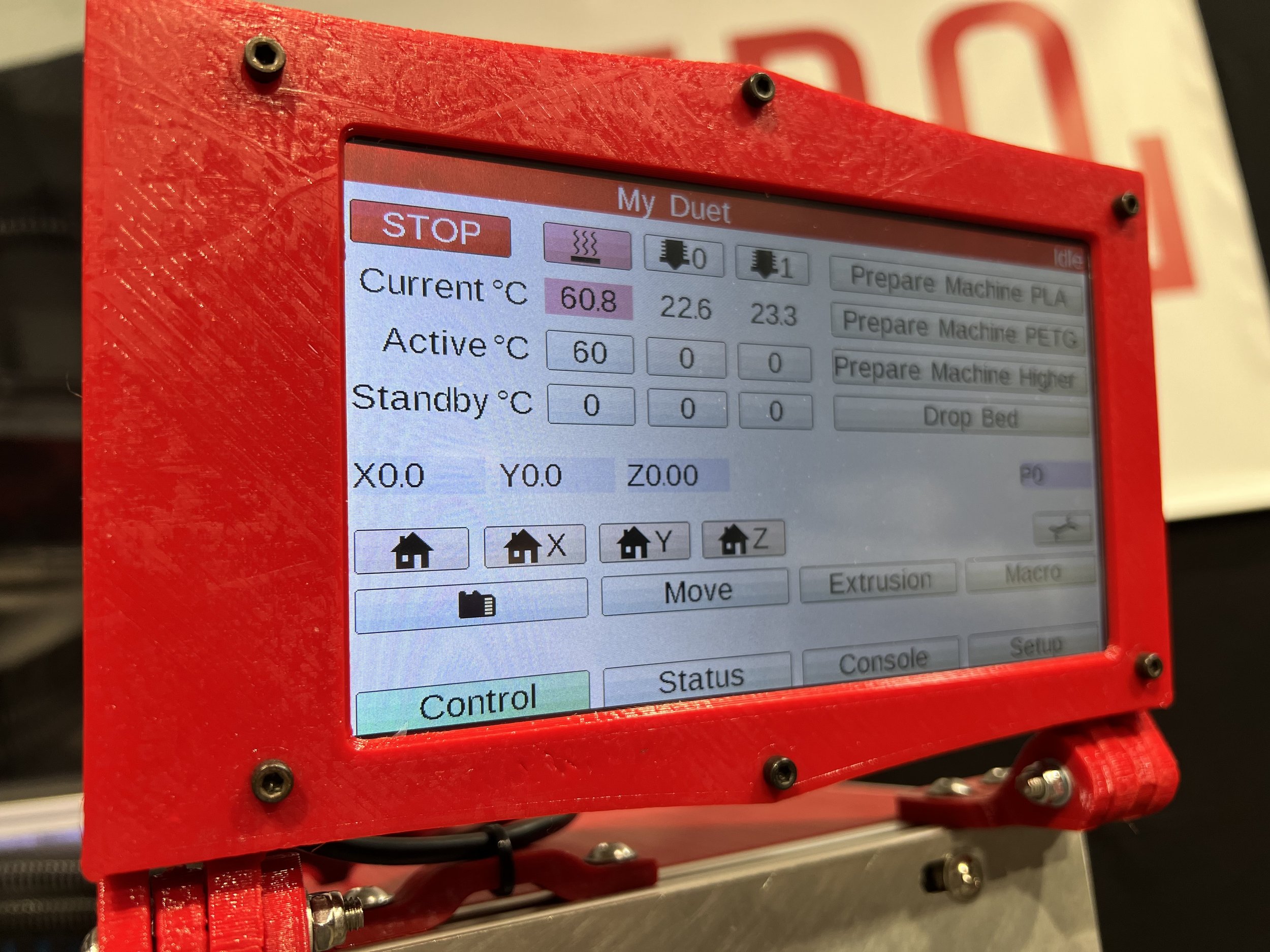

Control

A fast, capable machine requires a fast, capable control board. This is why we turned to Duet3D’s Duet 3 Mainboard 6HC. The 32 bit 300MHz processor allows us to implement advanced flow control and motion compensation algorithms.

-

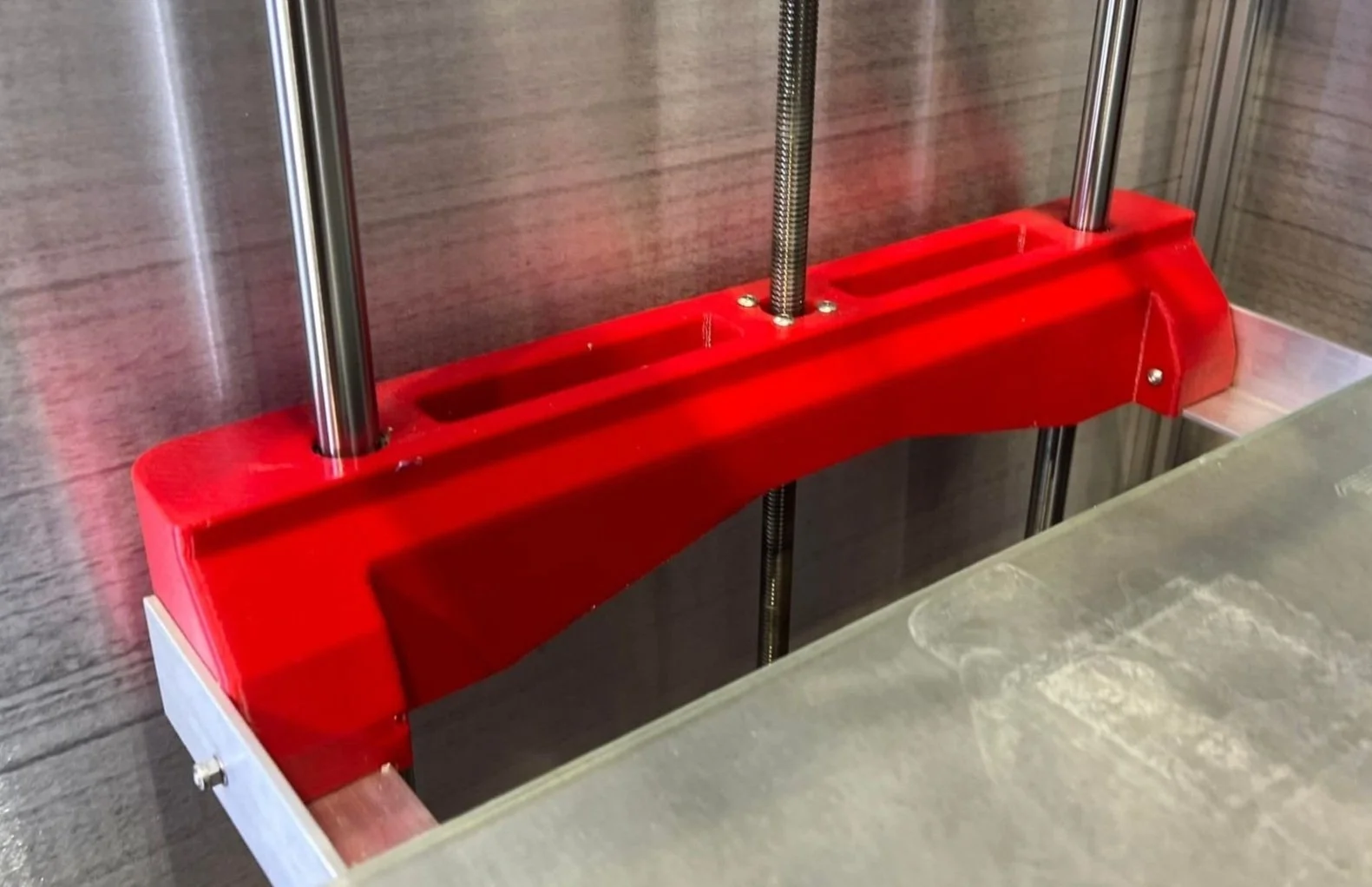

Endurance

From the oversized, double-length 16mm linear bearings to the high temperature Kevlar reinforced timing belts, everything about the 43 Series machines are built to last.

-

Design

A fully enclosed build chamber helps prevent warping. A build plate that moves only vertically ensures stability of tall prints. Direct drive extruders to more precisely control plastic flow. The way a printer is supposed to be.

-

Speed

High powered NEMA 23 size motors allow 43 Series machines to accelerate at over 1G and drive the print head at speeds of up to 12,000mm/min.

-

Interface

A 7 inch color touchscreen and wifi connectivity make operating your 43 Series machine a breeze.

“This printer definitely is a workhorse”

— Jake / Waygate Technologies Baker Hughes / 4310 Dual

43 Series Specs

Print volume

435 Single/Dual: 415 x 355 x 542 mm (16.3 x 13.9 x 21.3 inches)

4310 Single/Dual: 415 x 355 x 1042 mm (16.3 x 13.9 x 41.0 inches)

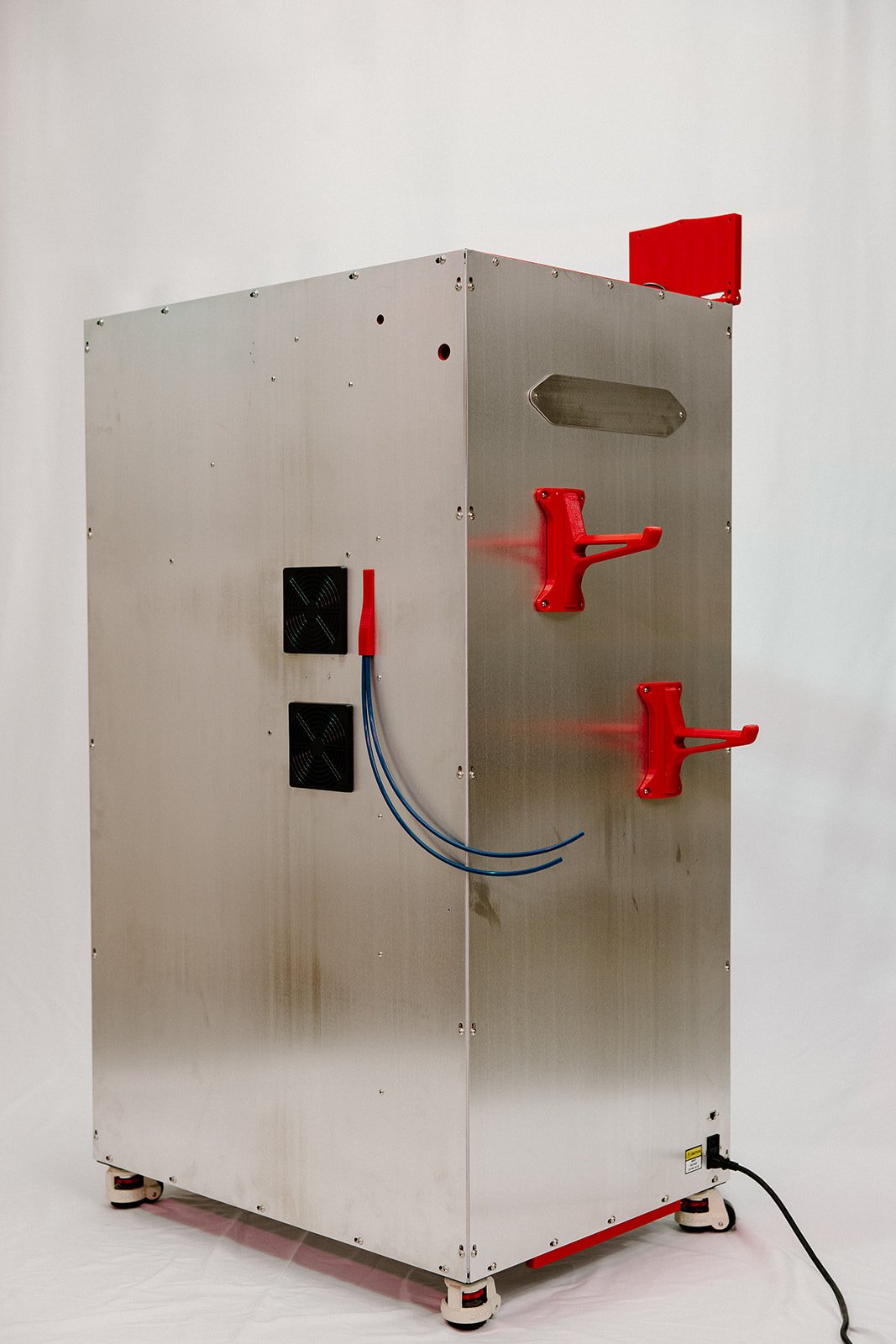

Machine dimensions (including touchscreen)

435 Single/Dual: 655 x 850 x 1110 mm (25.8 x 33.5 x 43.7 inches)

4310 Single/Dual: 655 x 850 x 1610 mm (25.8 x 33.5 x 63.5 inches)

Machine weight

435 Single/Dual: 170 lbs

4310 Single/Dual: 200 lbs

Power requirement: 120V 10A Single Phase

Control

Duet 3 Main Board 6HC with pressure advance and vibration compensation

Extrusion

Single or Dual extrusion

Filament Diameter: 1.75mm

Extruder: Bondtech LGX Pro, direct drive

Hot end: Chube Conduction (all metal)

Nozzles: Hardened Steel 0.6 standard, 0.2mm to 1.8mm available

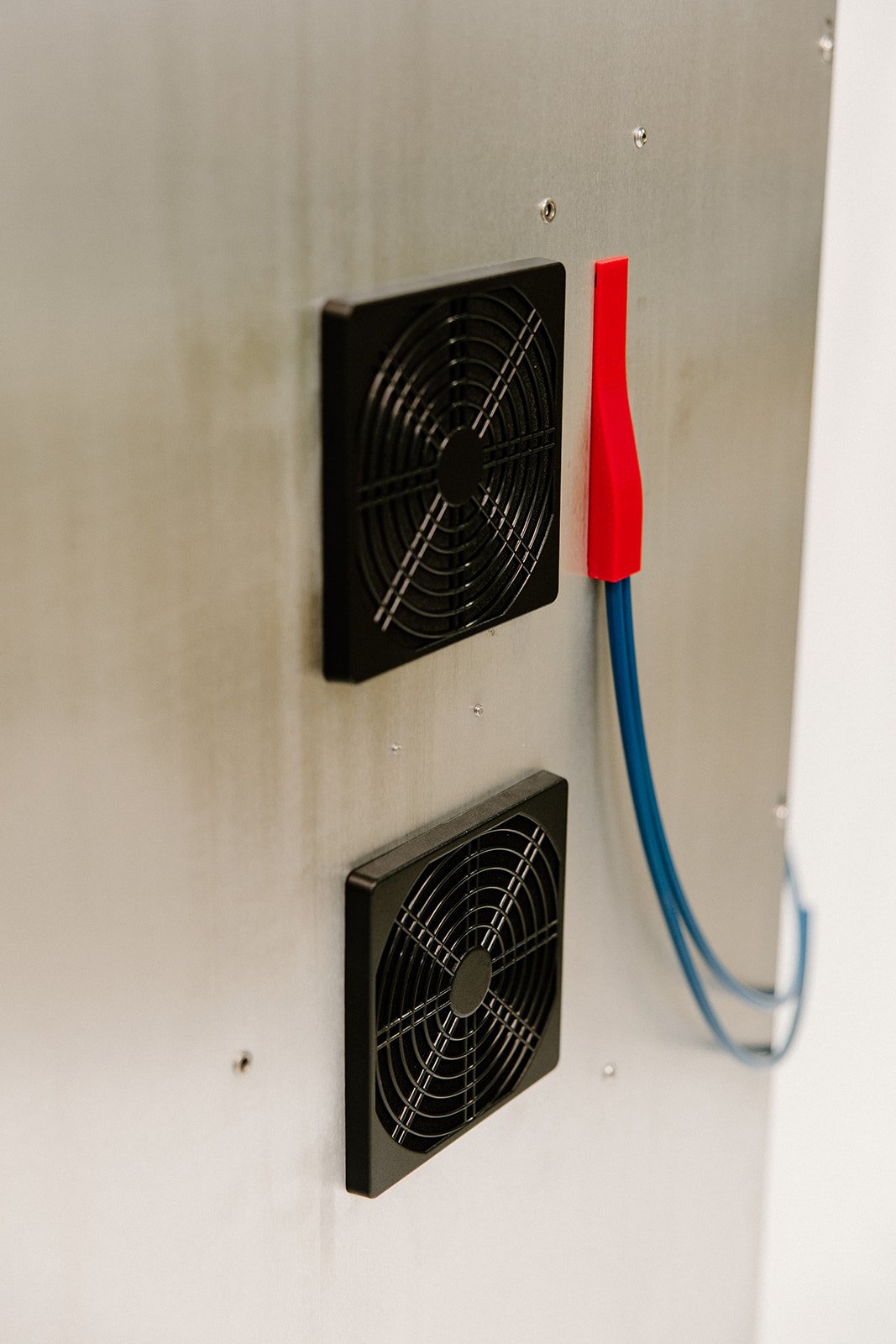

Part cooling: Remote mounted 120mm radial fan (per extruder)

Motion

Travel speed: 12,000mm/min

Acceleration capability: >1G

XY Motor size: NEMA 23

Linear bearings: 16mm diameter PBC linear shafting with double-length ball bearings

Software

Recommended slicing software: Simplify3D

Machine input: gcode, RepRap flavor

Interface

7 inch touchscreen

WIFI connectivity with web interface

Ethernet only available

Usability

Fully enclosed build area with adjustable lighting

BLTouch automatic bed leveling sensor with 374 point mesh bed leveling

Fume handling available

Adjustable leveling casters

Materials

Open materials system - no restrictions on material suppliers

Maximum extruder temperature: 380°C

Maximum bed temperature: 110°C

Includes 0.6mm nozzle Simplify3D profiles for: Recycled PETG, PETG, ABS, PA6-CF, PPS-GF, PPS-CF, Carbon Fiber PETG, TPU, Polycarbonate, ASA, Flame Retardant ABS, PLA, and many more in development

Ready to purchase?

Use the button below to navigate to our online store or click here to contact us for a custom quote

Mechanical hour meter for tracking preventative maintenance

Dual extrusion for printing complex parts with dissolvable support materials

Direct drive extruders for fine material control

Oversized XY motors, belts, and linear bearings for long life at high speed

7"color touch screen for complete machine control

Rugged aluminum panels add strength and stability to the high performance motion system

Big parts fast

Air filtration protects sensitive electronics from dust and dirt in manufacturing environments

Absolute unit